With hot stamping, a blank is heated to around 950°c to obtain an austenitic structure then, after stamping, rapid tempering (27° c/s min) is carried out in the same tool, to obtain parts with a 100% martensitic structure and very high mechanical resistance (Rm> 1500 Mpa).

LOIRE ETUDE is a specialist in the design and production of hot stamping tools, using complementary systems & resources. The installation of Robotic cells allows us to faithfully recreate conditions for production, & our hot forming simulations with Autoform Thermosolver allow us to anticipate and correct any design and manufacturing problems associated with the stamped material. We are also developing specific hot stamping parts such as tailored blanks (blanks made up of 2 grades of material), blanks of variable thickness, blanks with patches (blanks locally welded to the main blank) and semi-hot formed aluminum parts.

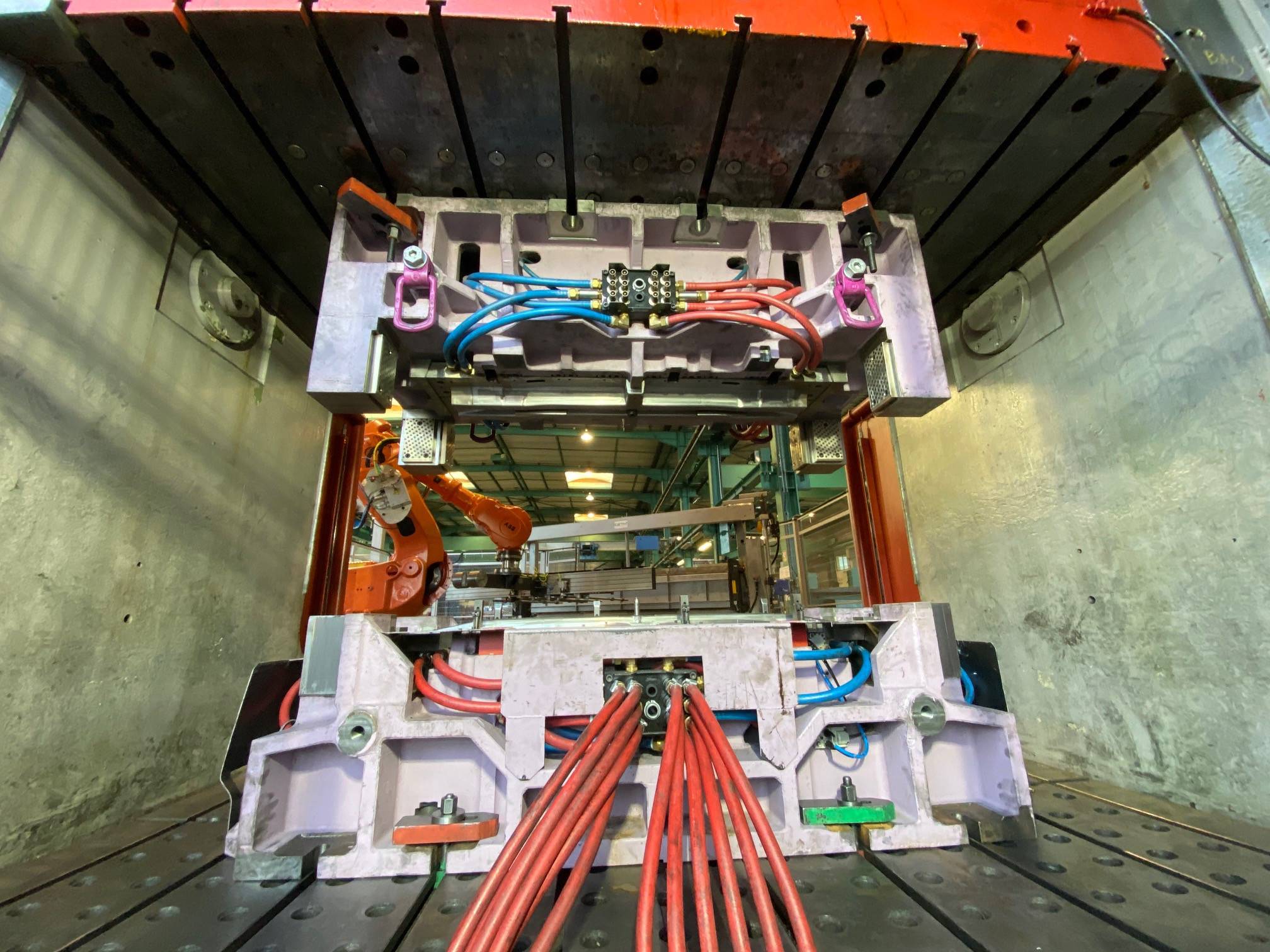

We have mastered various types of press hardening, in both direct stamping and indirect stamping. We also produce our hot stamping blades (with deep drilling operation) made of CR7VL, UH1, & even QRO90. We also offer a load shedding solution in the event of our customers' press failure, with a production capacity of 3x8, 7 days a week.

- Operations : 1

- Materials : 22MnB5 + AS150 / Thickness : 1 mm

- Prestation : Process, die design, tool manufacturing & home line tryout

- Dimensions : 3000*1750*1050 mm

- Cooling time : 7 seconds

- Pre-series production : 300 parts