Hot forming specialist, LOIRE ETUDE designs and manufactures Hot Forming and Super Plastic Forming tools. These forming technologies, mainly used in the aviation industry, allow the forming of low elasticity metals, such as titanium, aluminum and magnesium. By working the material between 900 and 1000° C, it becomes superplastic, and therefore easily formable and highly elastic. Gas pressure is then exerted on the heated metal in order to deform the sheet, placed between a punch and a die. This forming technique makes it possible to achieve elongation rates of over 300% and therefore to manufacture parts of great geometric complexity while limiting their spring-back and tearing. The advantage of SPF and Hot Forming is thus to form materials that cannot be cold formed, but for small volumes of parts. Indeed, the time for forming a part is long, ranging from 45min to 1 hour.

Loire Etude supports you in the design and production phase of SPF & Hot Forming tools. Our experience in various hot forming techniques allows us to offer innovative solutions to reduce the cost of tools or increase productivity.

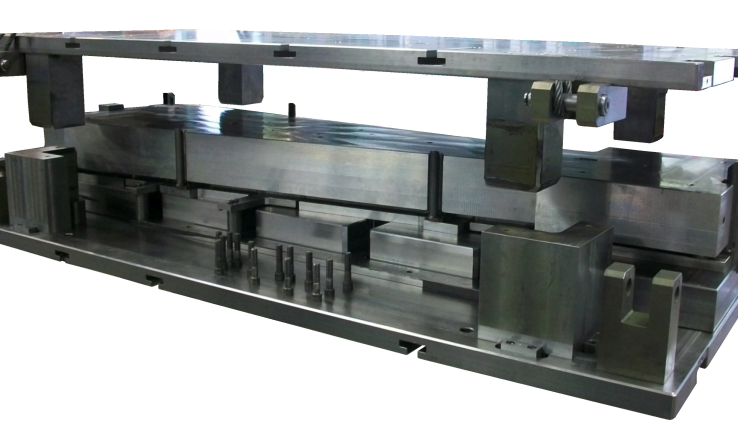

- Technology : Hot Forming

- Part material : TA6V / Tool material : X37CrMoV5-1

- Prestation : Process, die design, tool manufacturing & home line tryout

- Part dimensions : 2100*570*120mm

- Forming temperature : 730°C