Forming tools

Based in the Auvergne-Rhône-Alpes region, LOIRE ETUDE is a family business, which has been designing and manufacturing tools for forming materials since 1966. Reducing CO2 emissions, industrial performance and R&D are at the heart of our strategic aims.

0

Forming projects

completed

+0

Years

of experience

0%

Customer

satisfaction

0%

Export

rate

With European directives providing for a reduction in CO2 emissions of just over 35% by 2030, reducing vehicle weight is today a major challenge for all car manufacturers. Other sectors, such as aeronautics (with an increase in its traffic), the maritime sector (managing greenhouse gas emissions), and even material manufacturers find themselves impacted by these same issues: having to comply with the drive towards carbon neutrality. This not only requires new forming technologies, but also necessitates working with new materials such as aluminum, very high elastic limit steels and composites. Loire Etude is thus part of a process of improving the properties of your parts, allowing for weight reductions of up to 50%.

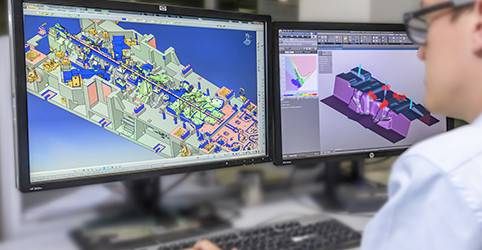

Innovation and new technologies are keys to remaining competitive and best meeting the increasing expectations of customers. As the market constantly evolves, whether in terms of materials (composites, steels, aluminum, etc.) or technologies (hot stamping, semi-hot forming, magnetic pulse forming), it is essential to know how to deal with new challenges. Our expertise allows us to support you through these technological transitions.

Combining the principles and foundations of lean engineering and manufacturing, we identify potential gains in terms of delivery time, cost reduction and waste, to provide you with the optimum product. We apply lean engineering throughout the product lifecycle, from conception and co-engineering work (feasibility studies) to design (simplifying and optimising specifications) and to manufacturing the final product.

Any project ? Contact us !